Bamboo has been used as a flooring material for over 5,000 years, but it gained popularity in its modern form around the 1990s. Because bamboo grows quickly and can be harvested more frequently, it's a cost-effective alternative to hardwood. According to Flooring Trends, bamboo used in floors can grow up to 47 inches in a single day and can be ready to harvest in around 50 days. Such rapid growth means that bamboo is more sustainable than other materials because it can be cultivated instead of harvested from wild forests, and in a fraction of the time. Because of the way its root system works, bamboo can regrow without replanting, making it a unique material in construction.

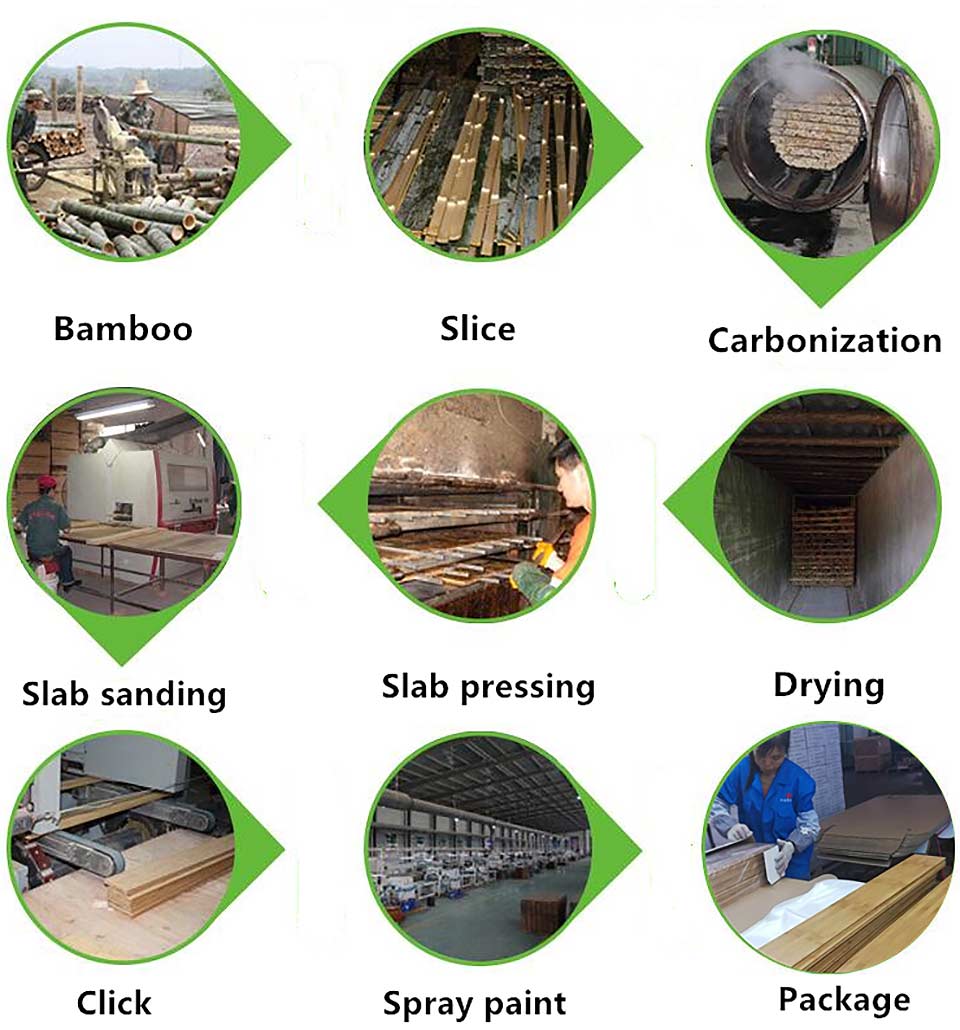

Bamboo floors are made from flattened bamboo stalks and can be very hard, although not always uniformly so. Since bamboo is a grass, it can be tricky to lay flat, and has gone through various types of flattening procedures to make it useful in modern construction. Once the material is flattened, it can be processed into planks just like regular hardwood and installed similarly in a home. Chopsticks Bamboo

Bamboo flooring can be very versatile, and installation options include glue, nails, and "floating" the boards over the existing floor surface. You can install bamboo directly over top of bare concrete, over a subfloor, or over another type of flooring, according to Bamboo Flooring Facts.

When gluing a bamboo floor directly to concrete, a water-resistant glue can be used to attach the floorboards to a concrete or plywood subfloor. This process is similar to laying tile, although the boards interlock so there's no grout line. All of the materials used for the installation should be acclimated to the room's temperature and moisture level for 72 hours prior to laying the floor. This will reduce shrinkage and swelling down the road.

To attach bamboo flooring using nails, the boards should be laid perpendicular to the floor joists, and nailed down using a pneumatic nail gun. If you choose to nail down your flooring, you should use an underlayment of felt paper or foam to cut down on moisture and to mitigate noise.

To float a bamboo floor, a wider board type is laid overtop of a cushion of underlayment. These boards are interlocking and can be attached together with glue, but not glued or nailed down. This can be a good option for a basement floor or a radiant heat floor.

Installing your own bamboo flooring is possible, but you will need some tools, and the project takes a lot of patience. For bamboo flooring, the prep is a time-consuming task, and Plum Prairie Ranch stresses that a lot of work needs to go into cleaning and leveling your surface before you start. Beginning with a flat, clear surface and having your underlayment laid out flat before you begin is the recipe for success.

Once you have your underlayment down, it's important to make sure that you have room for expansion joints if you're using a floating floor. This will keep the floor from bubbling or buckling as it expands and contracts with temperature and moisture changes. It's also important to remember that laying flooring requires a chop saw as well as other tools to complete the project, so you should factor that into your budget as well. Laying one room could take about 30 hours or so, taking into account prep and installation, to give you an idea of what you might be signing yourself up for as a DIYer.

Bamboo flooring can be cost-effective as compared to other options. According to Forbes, the average cost for bamboo flooring is $2.25 per square foot. There is a wide range of pricing for bamboo flooring depending on the type you use, with the low end being $1.50 and the high end being $11 per square foot. Different types of flooring can vary a lot, so checking the price tag will help avoid surprises.

To add the labor cost, you should expect to pay another $2.50 to $6.00 per square foot as installed, so keep that in mind when considering the price. The average cost to have 300 square feet of bamboo flooring installed in your home is $2,200, which includes labor and materials. To get a better sense of how much labor will cost, you might need to look up the average prices in your area, since there can be a big difference in cost depending on where you live.

Because bamboo flooring is made from a resource that will be ready to harvest in 3 to 5 years, and can be grown more densely than traditional lumber, it's considered to be a sustainable choice. For these reasons, its environmental impact is less than that of regular wood flooring during the process of cultivation, per NC State University. Using the method of life cycle assessment (LCA) to calculate the environmental impact throughout the whole process of growing, manufacturing, installing, and disposing of bamboo floors, some important distinctions can be made between the different types of bamboo floors.

During the manufacturing process, the sustainability of bamboo differs greatly by type. The scrimber type of bamboo flooring that uses strips of bamboo is more than one and a half times more environmentally friendly during the manufacturing process than the laminate type flooring. The other factor that makes scrimber type flooring better for the environment is that it tends to last longer, so less of it needs to be made and consequently disposed of. If your concern is environmental impact, scrimber bamboo flooring is the best way to go.

With flooring, water resistance can be a big issue because over time, wet feet, spilled drinks, and cleaning will introduce moisture into the floor's surface. According to Ambient, bamboo flooring is usually more water resistant than hardwood, but not completely waterproof.

It's important to take the type of flooring into consideration when determining water resistance. Bamboo floors that come with waterproofing finishes are usually undamaged by having standing water on them for a short time. Longer exposure to standing water can cause the bamboo to warp. Warping, also known as cupping, can also be caused by high humidity, moisture in the subfloor, and lack of time for acclimation before being installed.

Because of the danger of warping, bamboo has been thought of as a bad choice for kitchens, but strand woven bamboo, also known as scrimber, has a 20-hour water-resistant property that makes it much less susceptible to damage.

Kids and pets can be tough on floors, and their safety is always a primary concern. Weighing safety and utility can be tough when choosing a flooring product, but bamboo meets these challenges because of its density and durability. Bamboo flooring is manufactured in such a way that the material is very sturdy and stable. It doesn't need to be sealed, as it usually comes with a protective layer already in place, so it can be very resistant to all kinds of traffic.

As we've discussed, finished bamboo floors are moisture resistant, but they're also scratch resistant, says New Home Source. Bamboo floors will also resist staining, as the dense material they're made from isn't very porous and won't absorb liquids quickly. Because bamboo flooring is very dense, it will stand up to pet paws and LEGO bricks alike. Bamboo is also a safe choice as it doesn't splinter like hardwood can, as well as being less prone to mold, mildew, and other allergens.

Because bamboo flooring is manufactured using resins, adhesives, and finishing materials, one concern can be off-gassing, or the release of chemicals that can be toxic when inhaled. According to Home Building, in addition to looking for an EPA certification for your bamboo floors, you should also see what the manufacturer's environmental policies are. Being comfortable with the way that your floors are made can give you more confidence that they are safe.

Bamboo flooring falls into the category of composite or laminate flooring, so the EPA does issue certifications for some bamboo flooring products. While some types of laminate flooring can off-gas or emit harmful levels of formaldehyde, the EPA specifies that flooring with a TSCA Title VI label has met their specifications for safety. Since testing for formaldehyde inside your home once the flooring has been installed can be difficult and expensive, checking the label is the best way to avoid problems with formaldehyde or other harmful chemicals.

Bamboo can be either glued or floated over an existing concrete floor as long as the surface is properly prepared. Cleaning and leveling a concrete floor before installation is required for success, but the most important step, according to the Bamboo Flooring Company is making sure that the concrete is properly dried before installing the floor.

When prepping your concrete floor before installing your bamboo planks, you should use a digital hygrometer to make sure that the moisture level in the concrete is below 65%RH before attaching the floor. If the moisture level is too high, you can wait for the concrete to dry out more before installation.

To float your bamboo floor on concrete, you need to use a concrete-specific moisture barrier and make sure to cover the whole surface of the floor before you lay your planks. To glue your bamboo flooring down, you'll need to use a flexible adhesive so that the floor can move enough to not warp or buckle with temperature and atmospheric changes.

One of the biggest differences between bamboo and hardwood flooring is sustainability. Since bamboo grows very quickly and more densely than tree forests, it is much more efficient to cultivate and harvest than hardwood. According to Masterclass, bamboo flooring is often cheaper than hardwood, but this isn't always true. It's best to do a side-by-side comparison with the material you're planning to use in order to make the best choice.

For durability, hardwood and bamboo are neck and neck. Some types of bamboo are harder than some types of hardwood and vice versa. Using the Janka hardness scale is the best way to determine where your product will fall in terms of durability. Tiny Timbers explains that the Janka test is performed by pressing a .444mm ball into the surface of a board with a specific amount of pressure. The resulting mark will tell you how hard or dense the material is.

Since there's a lot of overlap between bamboo and hardwood in terms of density, they're both considered to be durable, with bamboo being more water-resistant than hardwood. They also both come with a variety of finishes as well, however, refinishing will require different methods depending on the type of flooring you choose.

Even though bamboo flooring is slightly more water resistant than hardwood, tempting fate by cleaning it with a soaking wet mop is still not a good idea. Oh So Spotless recommends using a dry mop for the day-to-day cleaning of bamboo flooring. A dust mop should be enough for most cleaning, but if you need to scrub a little more, you can use a slightly damp mop. A properly wrung mop can be achieved with a ringer that comes with a standard mop bucket.

Other tools that will work well on a bamboo floor include spray mops with a pH-neutral cleaning solution and microfiber cloths. These tools will clean the floor without scrubbing the finish off or getting the floor too wet. You can also use a vacuum on bamboo as long as it doesn't have stiff bristles that will scratch the finish.

Cleaning tools to avoid on bamboo floors are steam mops and wet vacs, which can almost instantaneously warp and buckle the boards. Anything that has an acidic content or that contains a lot of oil should also be avoided because these can damage the finish or stain the surface of the floorboards.

Bamboo flooring comes in three major grain types, according to Build Direct. These are differentiated by how they are manufactured, and they have different looks based on the natural fibers they're made from.

Horizontal bamboo is made from straight planks attached to each other horizontally, showing all of the natural aspects of bamboo material. The "knuckles" in the bamboo are visible in this grain type and appear like knots would in hardwood. Vertical bamboo is made from strands of bamboo attached to each other vertically. This type of board doesn't show the knuckles of the bamboo reeds like the horizontal type. It has a smoother, more uniform look. Strand-woven or scrimber bamboo flooring planks are made by weaving and pressing smaller strands of bamboo together. These have a mottled wood appearance and can vary greatly depending on the finish type.

Bamboo boards also come in three major finish types. Natural bamboo is a light color like dried grass and has no dyes or colors added to it. Carbonized boards are darker in color as a result of being heated for a longer period of time during the manufacturing process. The heat caramelizes the sugars in the bamboo, staining it a dark brown. Tiger boards are made from a mixture of bamboo from both natural and carbonized processes and are striped like a tiger.

Natural bamboo is light in color like blonde wood, so it can take a variety of stains depending on your preference. If you're using manufactured bamboo boards, you'll need to sand it down before applying the stain, per Architecture Art Designs. Then you can apply wood stain to the unfinished surface before resealing it. If you want to even out the color of the floor, you can use stain to try and match the darker color in some areas. You should use a rag to apply the stain evenly and then wipe away any excess after 2 to 3 minutes. If the stain doesn't achieve the desired darkness after the first application, you can apply a second coat. It's always better to apply the stain in moderation as it's much simpler to add more than it would be to remove.

If you're using an unfinished bamboo product, you may still need to do a little bit of sanding, according to Amazulu Inc. That's because bamboo, like smaller species of grass, has a waxy outer layer that will repel moisture and thus not absorb the stain well. Making sure to thoroughly sand the surface of the board will allow the stain to penetrate the surface.

If your bamboo shows some wear after a few years, the good news is that you can sand and refinish it. While bamboo isn't actually made from wood, but from strands of a large grass woven together, it still has a lot of the same properties as hardwood. According to How to Sand a Floor, you can remove old finishes, dents, scratches, and worn areas from a bamboo floor by sanding them out. You can also apply new finish to the floor just like you would for hardwood.

If you choose to do the sanding yourself, it's important to make sure that you have good dust extraction in place. The dust from floor finishes and from the adhesives used to bond the bamboo itself can contain small amounts of formaldehyde as well as other irritants. Wearing eye protection and a properly fitted dust mask as well as making sure that your worksite is well-ventilated can all help keep these hazards to a minimum.

Bamboo floors are a good investment because of how durable they are. Long-lasting materials are generally a good choice when installing floors because they can be so expensive to replace. According to Floor Factors, while bamboo flooring doesn't have the same return on investment as hardwood, it will still add value to your home because of its sustainability, water resistance, and look. You can also plan on selling more quickly after installing good-quality bamboo flooring.

Engineered Bamboo Floor Because of bamboo's popularity, Wheat's Flooring and Home points out that installing good quality bamboo floors can boost your home's value. The price point of bamboo is low enough that it can be an affordable option to boost your ROI. Because of its durability and sustainability, home buyers will be attracted to bamboo as a flooring material. The best way to make sure you get plenty of ROI from your bamboo floors is to make sure they're installed correctly. Home buyers don't want to inherit a warping, uneven floor that will need to be replaced.