American company expands melt shop in Norway to produce recycled-content aluminum.

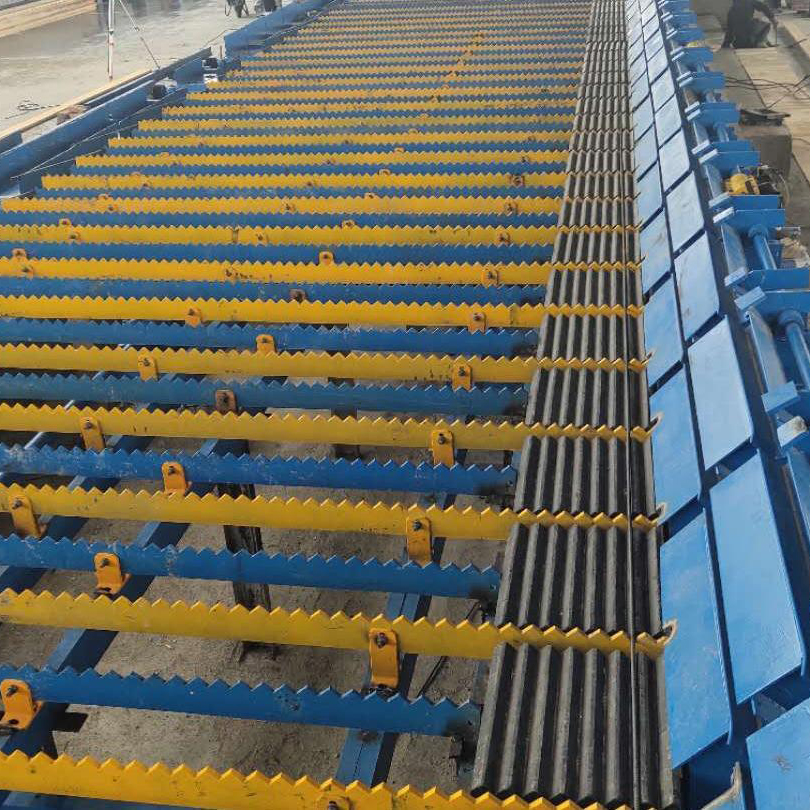

Pittsburgh-based aluminum producer Alcoa Corp. says it has installed a new furnace at its Mosjøen smelter in Norway to make the facility the home of the company’s “largest investment in recycling infrastructure.” section straightening machine

Alcoa says it has completed the installation of an induction furnace that uses renewable energy to recycle aluminum scrap, “saving energy and unlocking the infinite recyclability of our metal.”

The investment in Norway comes at the same time rival Norway-based aluminum producer Hydro also has made major investments in scrap melting technology, both in Norway and in Michigan in the United States.

The Alcoa Norway project stems from a collaboration between Alcoa and MMG Aluminium, a German-based metals trading company that supplies Mosjøen with clean aluminum chips and shavings that have been compressed into briquettes, says Alcoa.

The induction furnace melts the briquettes and then pours out the recycled-content aluminum for blending with the smelter’s primary (but low-carbon) aluminum and various alloying materials, depending on the end-use applications. End markets for the recycled-content aluminum include beverage cans and components for electric vehicles.

Mosjøen’s induction furnace runs on electricity sourced from wind and hydropower and uses alternating current that runs through a resisting coil, creating heat. That heat melts the scrap while removing impurities before pure market-ready aluminum is poured off via the furnace’s tilting mechanism, says Alcoa.

Alcoa calls the new induction furnace Alcoa’s induction furnace was its single largest return-seeking capital project in 2021, and says it was built in 10 months—a quick turnaround time compared with using many other furnace technologies.

“We have been working with the plant in Mosjøen for more than 15 years, and we are happy to see our long and steady relationship grow with an increase in the site’s recycling capabilities,” says Guenter Strobel, CEO and founder of MMG Aluminium. “We see Alcoa as the right partner for this project, which combines green energy to power a new furnace with the high-end quality standard of the products that we get from Alcoa Mosjøen.”

Alcoa and MMG say the furnace is charged, tended, cleaned and robotically skimmed using an automatic system. The induction furnace is able to operate semi- autonomously using sensors and guiding systems. “This is particularly helpful when blending scrap metal with primary aluminum to perfectly match the customer’s needs,” state the companies, adding, “By analyzing the scrap and making advance calculations, customer requirements are fully met in terms of purity, alloy content and any specific needs.”

Alcoa calls the Norway project one of several underway to contribute to its decarbonization efforts, along with its technology roadmap and its existing Sustana line of products designed to help customers reduce their carbon footprints.

Corrugated packaging producer raised prices throughout its fiscal year to cover rising “input” costs.

United Kingdom-based paper packaging producer DS Smith PLC says it expects up to $768 million in adjusted operating profits for its fiscal year ending at the end of this April.

In a trading update issued to investors, the firm and its Group Chief Executive Miles Roberts cite “continued momentum [with] good progress in profitability and cash generation” during the previous six months.

The company says it has used “continuing packaging price increase” that have “more than offset ongoing input cost increases.” Among its input materials are old corrugated containers (OCC) and other scrap paper grades used to make its containerboard.

As to its finished products, DS Smith reports “like-for-like corrugated box volume growth of at least 5 percent for the year,” referring to the period from May 1, 2021, to April 30 of this year.

Although Russia’s invasion of Ukraine has produced ripple effects in terms of energy costs and other factors, the company says its “only involvement in these countries is a minority investment in a Ukrainian business [that] serves customers predominantly in Ukraine with, limited sales in Russia. We have no other operations or employees in Russia.”

States Roberts, “I am pleased with the continued momentum and performance of the business in another year disrupted by COVID-19 and macro-economic uncertainty amplified by the Russian invasion of Ukraine. We have seen continued good momentum across our customer base, with volumes from our fast-moving consumer goods customers growing particularly well, underpinned by consistently high levels of service and product quality.”

Roberts says DS Smith’s Eastern and Southern European regions “have performed ahead of the group average,” while in the United States the company is “seeing the benefit of the Indiana site contributing to further very strong volume growth in the region.”

Adds Roberts, “We have continued to make good progress in our sustainability goals, and in January 2022 we committed to align our global operations to the sector leading 1.5 degrees Celsius scenario as set out in the Paris Climate Agreement.”

He concludes, “We have continued to invest in our business, leveraging our scale, our deep customer relationships and sustainable innovative solutions to lead the transition to a more circular economy, providing a strong platform for growth. We are mindful of the volatile macro-economic environment but have to date seen little or no evidence of changes to customer behavior and we enter the next financial year with confidence.”

The company will showcase its Meridian Front Loader combined with its Latitude residential collection system.

McNeilus Truck and Manufacturing Inc., an Oshkosh Corp. company based in Dodge Center, Minnesota, will feature its latest in refuse collection vehicle advancements and technology at WasteExpo, May 9-12, at the Las Vegas Convention Center.

The company will showcase its Meridian Front Loader combined with its Latitude residential collection system that offers an upgrade to residential front loader truck routes. The company also will feature enhancements to McNeilus’ Zero Radius Automated Side Loader equipped with CartSeeker Curbside Automation technology and ClearSky by McNeilus telematics. The new Metro Pak Plus Rear Loader also be featured in a display outside the West Hall of the convention center.

The company says attendees also will learn more about electric refuse collection vehicles with McNeilus’ patented electric-PTO technology.

“We’re always looking to the future and where the industry is going – looking for opportunities to help the industry evolve. What we’re exhibiting at Waste Expo this year is just a preview of where McNeilus is taking refuse collection,” says Jeff Koga, vice president and general manager, McNeilus Refuse Collection Vehicles. “We’re excited for customers to get a look at some of our latest innovations and learn more about what’s ahead.”

The company also rebranded its replacement parts business. Now, McNeilus offers two distinct options for getting customers the parts they need, no matter the makes or models in their fleets.

The tray is made from 100-percent-recycled PET and is widely recyclable in Canada and limited U.S. communities.

Cascades Inc., a Kingsey Falls, Quebec-based packaging producer, has announced the expansion of its eco-friendly packaging line with the addition of a 100-percent recycled polyethylene terephthalate (PET) tray which can be widely recycled in Canada and is recyclable in limited communities in the United States.

The company says the composition of its tray and optimized design for recycling make it an alternative to other hard-to-recycle food packaging, and adds that the design makes the tray compatible with packaging equipment already in use by food processors and retailers.

"This latest innovation is the fruit of our continuous efforts to find more sustainable solutions and develop a truly circular economy for food packaging," says Luc Langevin, president and chief operating officer of Cascades' specialty products group.

According to Cascades, the PET tray took three years of research to develop what it calls a unique design that allows for minimal use of materials while ensuring optimal rigidity, and its rolled edges reduce the risk of tearing when using shrink-wrap, helping to prevent food waste. The company also says the desire to include the product in the "logic of circular economy" was a priority from the outset of its design.

The material used to manufacture the tray is compliant with U.S. Food and Drug Administration and Health Canada requirements and made in an SQF-certified facility, according to Cascades.

The tray is manufactured in Quebec at Cascades' Inopak facility, which has gained more than $30 million from an investment program aimed at supporting the development of packaging made from 100-percent recycled PET flakes. The investments are part of Cascades' plan to grow its eco-friendly packaging footprint in North America and contribute to what the company says is an achievement of one of its goals in its Sustainability Action Plan which is that 100 percent of its manufactured packaging be recyclable, compostable or reusable by 2030.

In February, Cascades unveiled its three-year strategic update, which pointed to projected growth in the tissue sector and increased containerboard capacity thanks to its Bear Island, Virginia, mill project. Company President Mario Plourde at the time referred to Cascades as the sixth-largest containerboard producer in North America and added that one of its top priorities was the Bear Island project as well as "accelerating the pace of new sustainable product development and commercial launches."

Generac has named Worx an exclusive dealer of the Dust Fighter 15000 and 20000.

C.W. Machine Worx, Carroll, Ohio, and Generac, Waukesha, Wisconsin, are partnering to offer customers a cost-effective dust suppression product. Generac recently named Worx as the exclusive distributor of the Dust Fighter 15000 and 20000 models in the United States. Both options will be available to rent or purchase through Worx’s dealer, Company Wrench.

The DF 15000 and DF 20000 are midsized units capable of reaching throw ranges of 150 and 200 feet. Both Dust Fighters are equipped with Generac generators and are mounted on trailers. Although the specifications are generally similar, the Dust Fighters weigh less than competitive models. This makes transporting dust suppression equipment to multiple job sites easier and more affordable,

Worx says it is no stranger to the Dust Fighter product. The company says it was the authorized Dust Fighter distributor 13 years ago when the product was owned by Tower Light. Worx stopped offering the Dust Fighter product to focus on manufacturing its own domestic dust suppression product line. After successfully introducing the Dust Destroyer to the market, Worx began exploring other ways to establish itself as the leader in dust suppression equipment and technology.

“All of our dust suppression products, including the DF 15000 and DF 20000, feature a wheelless base design,” says Hugh Gordon, Worx’s project manager. “Instead of using tricycle wheels, which can tip over if it’s top-heavy or stuck in a groove, Worx’s balanced trailer allows for increased stability and mobility.”

The company says reintroducing the DF 15000 and DF 20000 allows WORX to diversify its fleet with cost-effective options, which are appealing to a wider customer base.

hot mill For more information about the Dust Fighter, other dust suppression machines or custom fabrication services offered by Worx and Company Wrench, click here.